About Our CNC Process

With our precision CNC machining process you can count on accurate and consistent results across the final product. Whatever your parameters may be, our years of experience have allowed us to take on most challenges with confidence. We’ll provide you with the support you need to automate your drilling projects.

Pricing

One Face/Side: $3.00

Each additional face/side: $1.00

Slot or Pocket: (over 0.5 inch) $1.00

Common Drill Templates

Click on your enclosure drill template below and download the PDF to start working on your machining layout. If don't see your size, contact us and we will see what's on file.

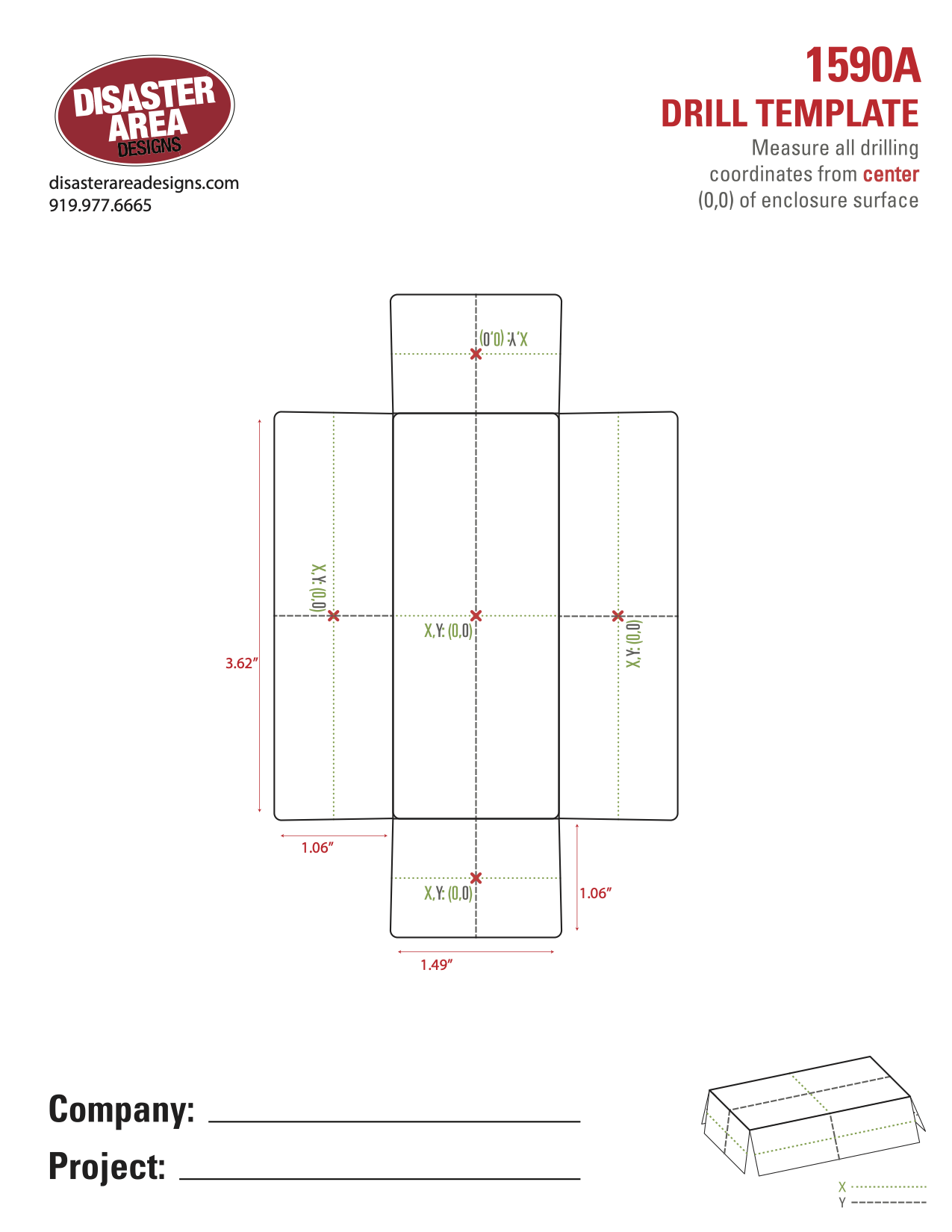

1590A, Twinkie

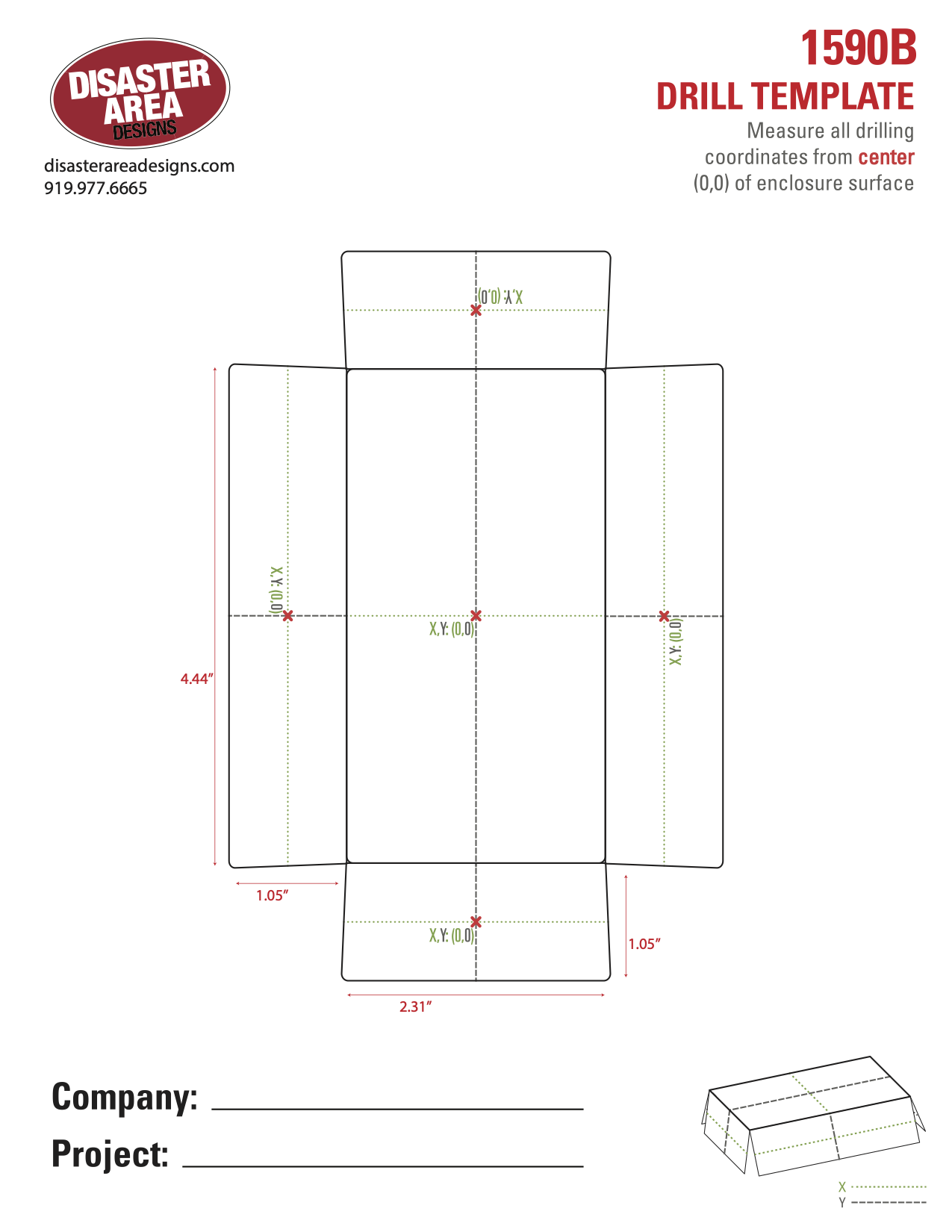

1590B, B size

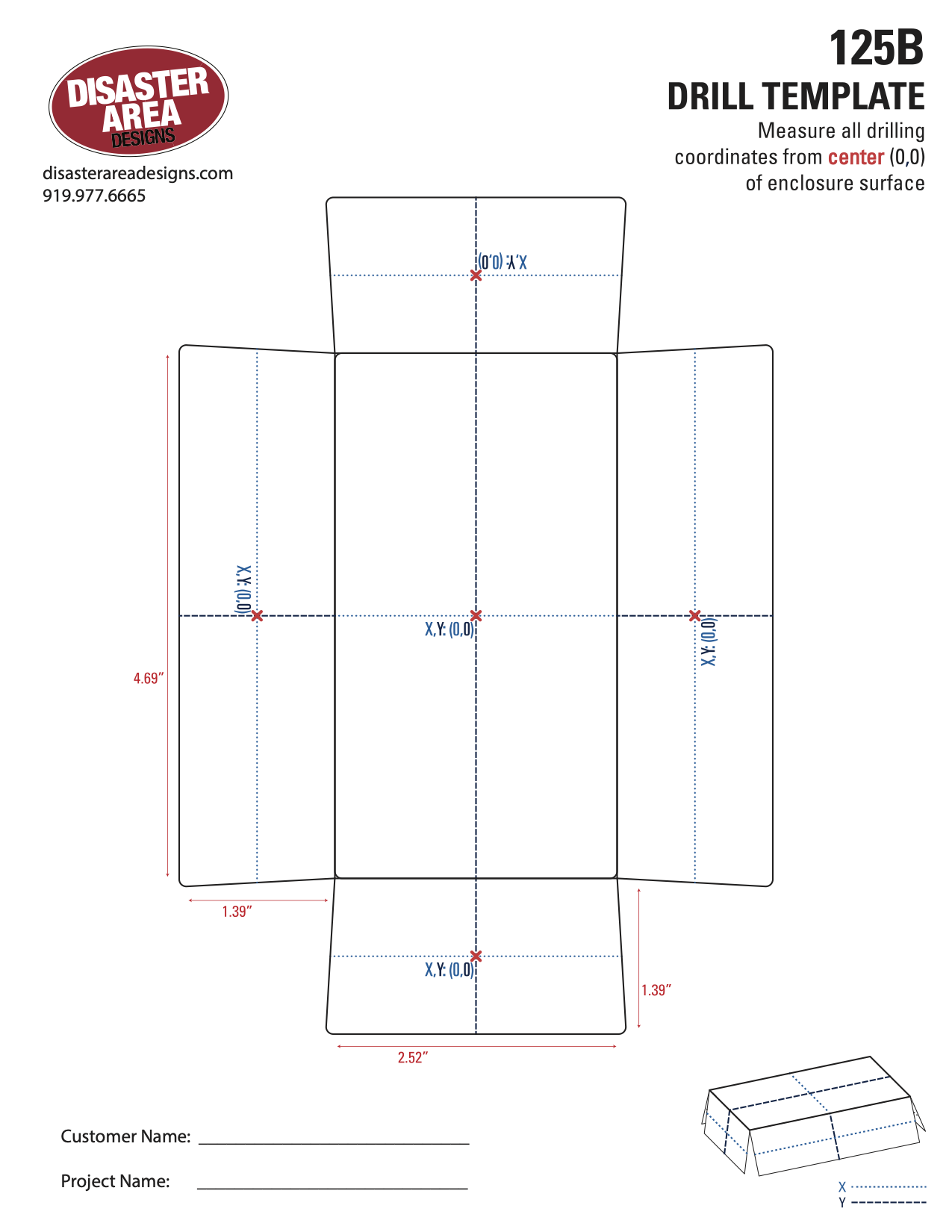

125-B

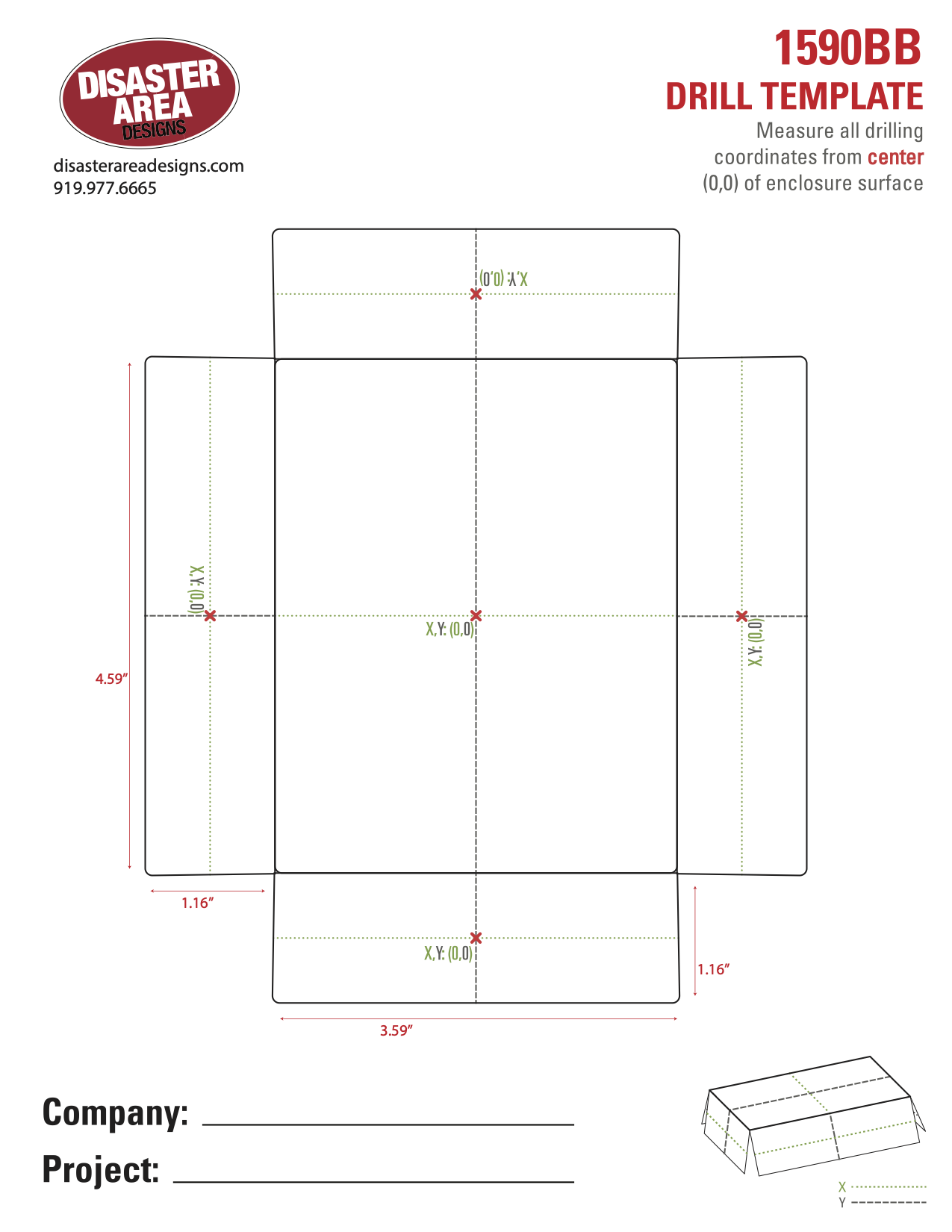

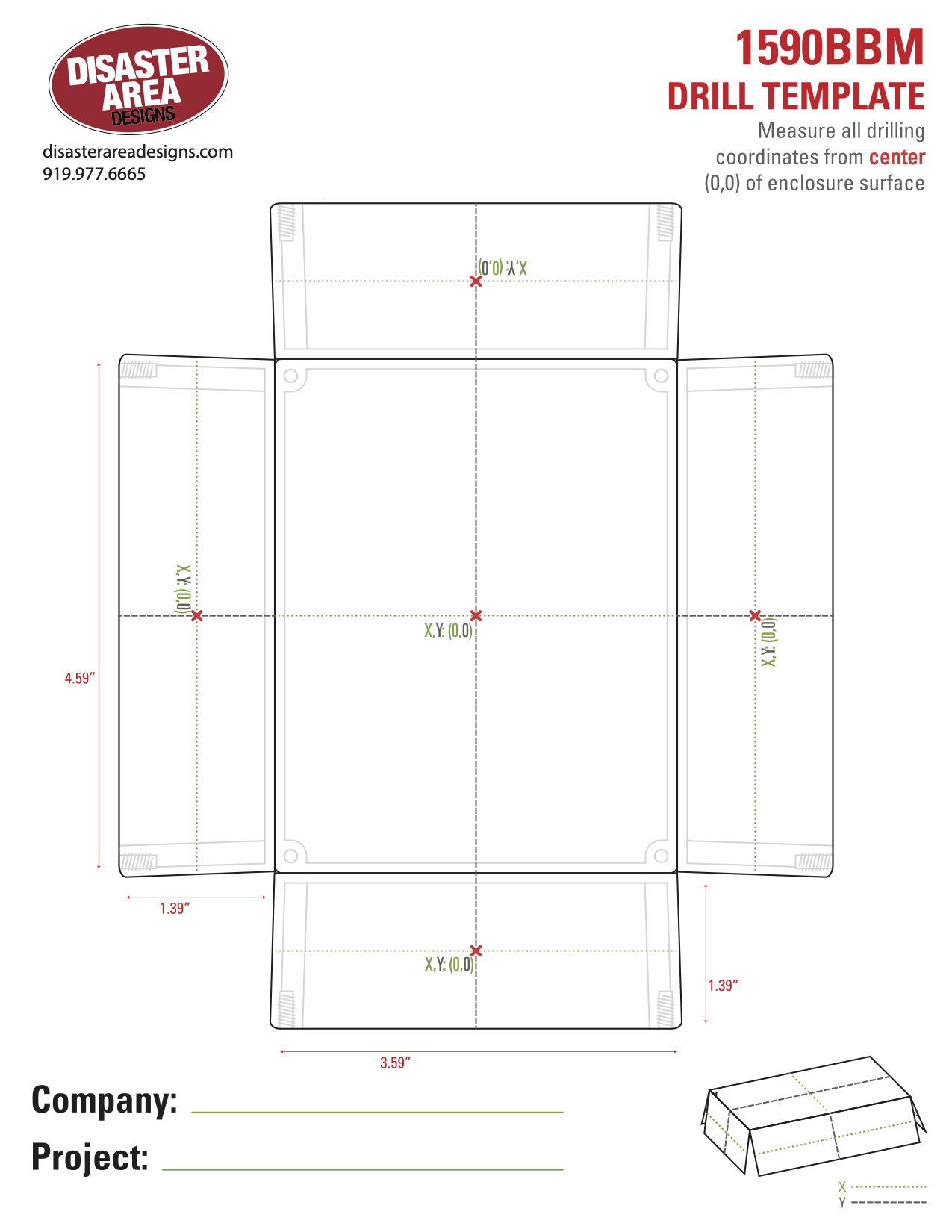

1590BB, BB Size

125-BB , 1590BBS

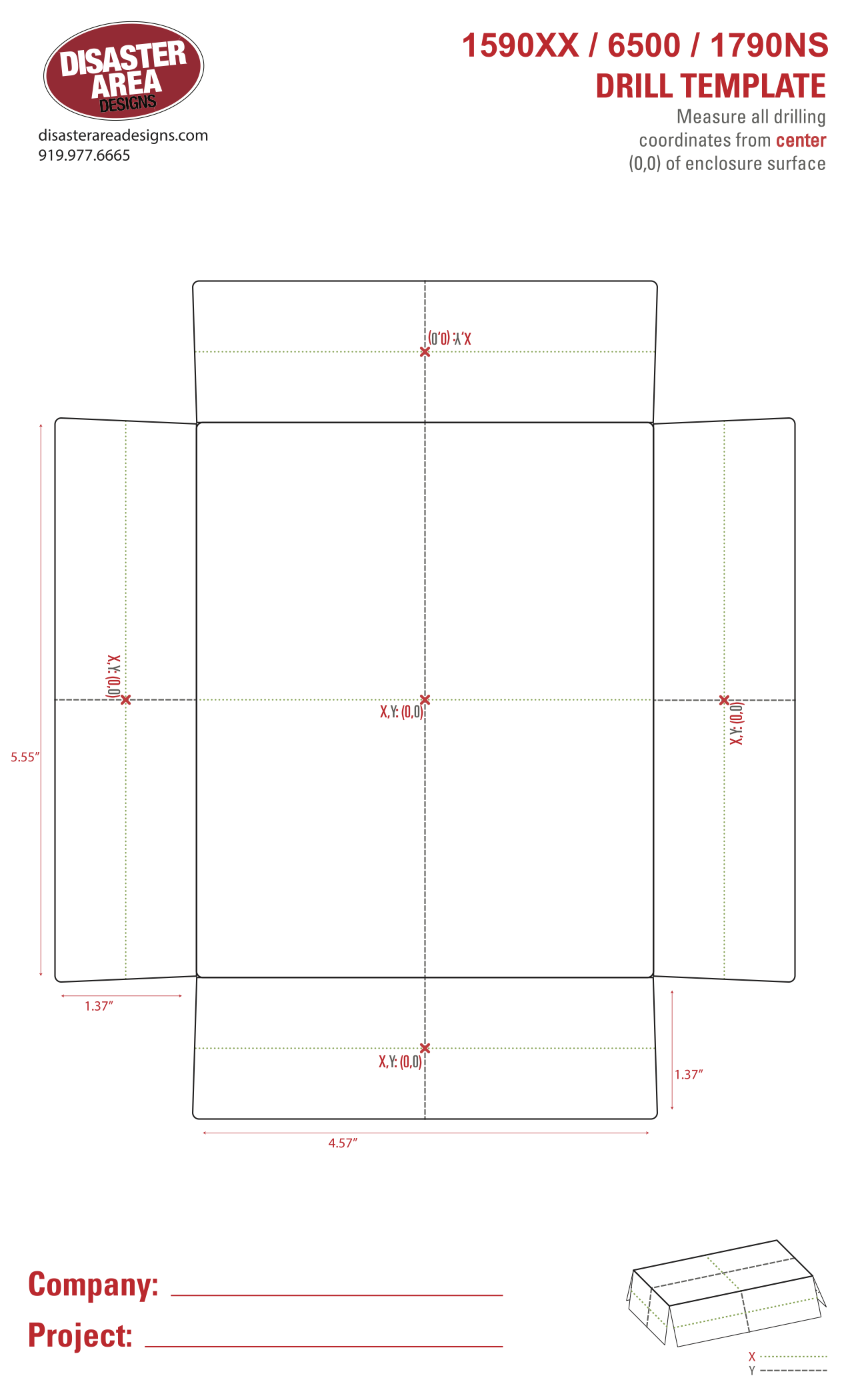

1590XX, 1790NS

How to set up your drill template for machining.

Even if you have your drill template sorted out, make sure that your method applies to our process. You may be familiar with the Cartesian coordinate system used in Algebra. Some of you may find this intimidating and probably a bit daunting but in fact it is quite simple and allows for communicating the exact placement of your drills.

Make sure to find the center point of the enclosure face(s) that you'd like to drill. Your center will be where the halves of both the lengths meet on any face. Once the center has been determined, you will have an x,y axis with four equal quadrants on which your coordinate axes will be found. Each drill mark will be labeled with the distances from center for both x and y axes.

The use of negative and positive numbers are used to indicate which quadrant a coordinate axis lives in. Any measurements below the center point of the Y axis and left of center on the x axis are considered negative numbers. For example, if you want to mark the placement of a foot switch two inches below center but lined up with the center point of the x axis simply right (0,-2) as your coordinate. If you want to offset the drill point two inches to the right, it will read as (2,-2). Two inches to the left and you turn that first number into a negative number, (-2,-2).

Above are templates of our most common enclosure sizes with the x,y already drawn on all corresponding faces. Even if you have other shapes, finding the center point of any drill must be determined first, then we can input the dimensions of that shape around that point.